Concrete Leveling and Lifting in Logan, UT

Why is Uneven Concrete a Problem?

Why Does Concrete Settle?

There are several reasons why concrete settles. Here are some of the following:

Base

The stability of a concrete slab depends on how compact its base is. If the base materials have not been compacted correctly before pouring, this leads to unstable settling. The concrete gets heavier as it cures, and this weight will continue to add to the problem. As a result, settlement kicks in, and it can happen pretty quickly.

Climate

The freeze and thaw cycle experienced in many regions causes the ground underneath the slab to expand when frost is present. This in turn will cause slabs to heave or raise. When the frost melts the slabs will settle and most often not to their original elevation. Slabs may become uneven resulting in trip spots. Drought often causes soil, such as expansive clays to shrink causing settling issues for concrete slabs. When expansive clay soils encounter wet conditions, they may swell leading to shifting concrete that needs leveling.

Erosion

Many different factors can lead to eroded base materials under concrete. Damaged water lines or sewer lines can lead to washout of base materials causing slabs to settle. Improperly placed downspouts can cause pooling of water, which can lead to erosion.

Machine/Traffic Vibrations

Concrete slabs may move or settle in industrial/highway settings where movement and heavy loads are present. The vibrations from the machinery and passing traffic can lead to the base compacting and the slab's settling or slab movement.

Slab Curl

Slab curl occurs when a relatively large section of concrete is poured. During the curing process, the top of the slab may cure slightly faster. This leads to slabs that curl and may rock and become unstable. Vibration may also cause slabs to eventually settle.

How Should I Repair My Settled Concrete?

There are several ways you can repair your concrete problem.

Joint/Slab Stabilization

Slab stabilization is often required when slabs lack support, but may or may not be settled. Slabs can crack when loads exceeding its capacity are applied. Slab/joint stabilization applications require the voids to be filled to eliminate slab movement and offer support. HMI foam specifically designed for joint/slab stabilization has a very long reaction time and minimal expansion strength. It will take longer to expand, allowing for better coverage under the slab or down a void along a joint.

Void Filling

Concrete settling is not the only issue that HMI Foam can solve. Voids under slabs are often present in areas where wash out or excessive settling can occur. HMI material will weigh on average 15-25 times less than a traditional mud jacking or cementitious grout mix. This lightweight material will put less stress on an already failed sub-grade. The process of drilling, port installation, and injecting the material is the same as the raising process. All dual component polyurethane foams create heat when installed. Void fills must be done in a layering method to allow heat to dissipate safely.

Replacement

This method may lead to downtime for businesses, loss of productivity, and lost revenues. It is very time-consuming and the most expensive. You may have to worry about the color, for the new slab will not match the existing adjacent concrete.

Grinding

This is an inexpensive option that is unattractive. Grinding exposes aggregate in the concrete which makes this unappealing. The integrity and strength of the slab are also compromised when using this method. Slabs that continue to settle after grinding cannot be raised back to their original levels.

The Best Method to Raise Your Concrete:

The Deep Foamjection Way

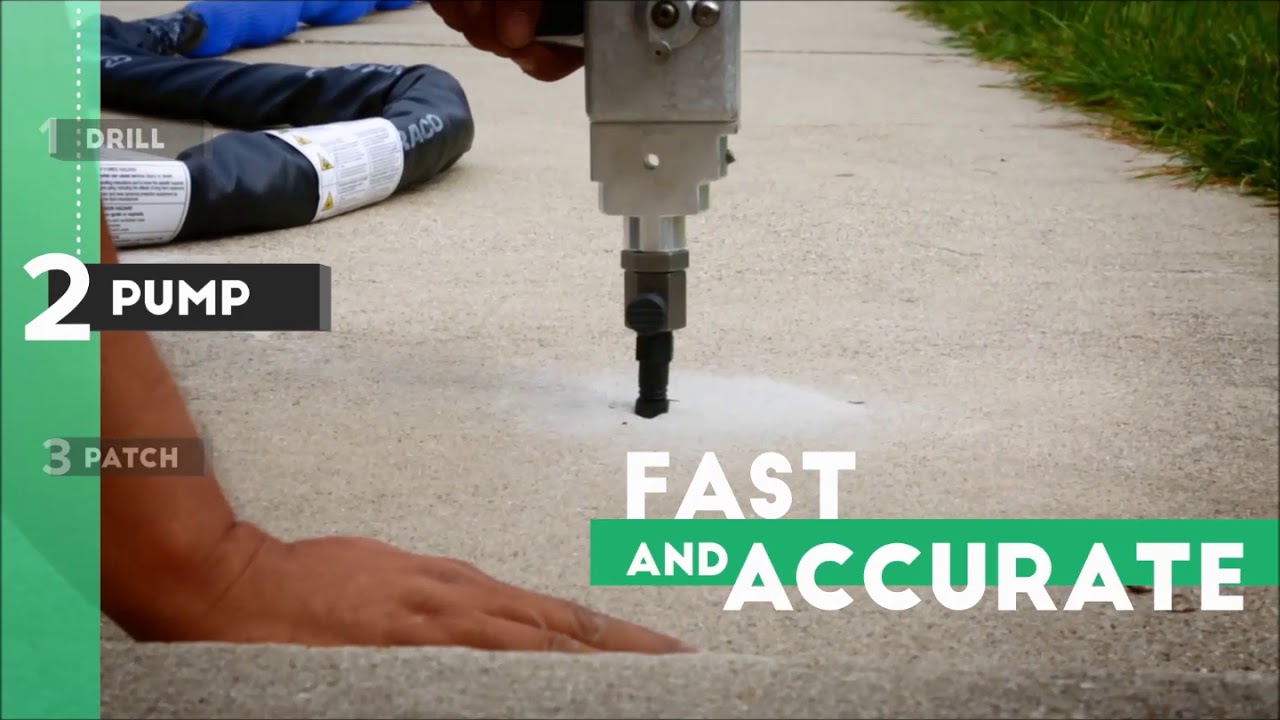

What we do is inject polyurethane foam beneath your concrete and raise it up that way. This is the best fix because it gets to the root of the problem, the unstable soil. The foam strengthens the soil, giving the concrete a more sure foundation which in turn makes it less likely to sink in the future. Here are the steps of our process

Expansion of the material occurs within seconds, compressing loose soils and raising concrete. Raising concrete with polyurethane foam is done with controlled incremental injections. Lifting foam will fully expand within 10-15 seconds. This allows the applicator to monitor the raise and prevents over raising the slab. HMI suggests using air purged equipment to deliver foam under the slab. This equipment will keep the injection port open between injections, allowing for the installer to wait for the foam to fully expand before injecting more material.

The process of raising concrete with HMI foam is inexpensive when compared to replacement.

It is also exponentially faster than the replacement method. Repaired areas are ready within minutes to be utilized, as they were intended to be. Ease of process, material, and clean-up are advantages over traditional mud jacking repairs made with grout.

Our Deep Foamjection Solution

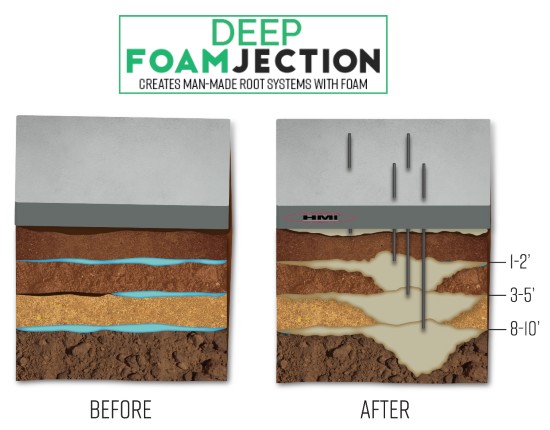

What is Deep Foamjection?

Deep Foamjection is the process of installing foam deep into the ground to increase the load-bearing capacity of the soil.

The foam follows the path of least resistance and just like a tree, creates roots that expand out, filling fissures and ground voids. This stabilizes the soil, protecting it from erosions and shifting.

Watch Our Foam in Action

We use a revolutionary process in the concrete raising industry known as Deep Foamjection. As you can see in our video above, our Polyurethane foam expands and settles quickly. This allows us to get to the root of the problem, the unstable soil, getting you the best permanent solution on the market.

We use the revolutionary technology known as Deep Foamjection to raise and level your concrete. It is the BEST solution to solve your concrete problem because it is:

A Permanent Fix

The reason your concrete has lifted is because of unstable soil. With Deep Foamjection, we administer a light polyurethane foam deep into the ground, stabilizing it, unlike mud jacking or replacing the concrete will do.

Quicker

Mudjacking and replacement take hours or even days before you can use your driveway again. With us, your surface can be walked on, played on, and driven on immediately.

The Best Value

Deep Foamjection is half the price of replacement and gives you the best bang for your buck.

Greener

Our foam is top-of-the-line eco-friendly material, and every time you choose to raise rather than replace, you are saving landfills from massive concrete slabs.

What People Are Saying About Us Online

Your Concrete Leveling and Foundation Repair Experts in Utah

- Logan

- Smithfield

- North Logan

- Hyrum

- Providence

- Nibley

- Hyde Park

- Wellsville

- Richmond

- Millville

Frequently Asked Questions

Usually around 50% or less than replacing.

Cheaper, quicker and cleaner than a new slab, and ready to use instantly

It is a long term solution for settled concrete.

Most jobs can be done in less than 1 day and ready to use immediately

Bad compaction, freeze-thaw from winter, poor drainage

Cracked concrete can be leveled